CWST will be exhibiting at the MedTec UK exhibition at Coventry Building Society Arena on the 12th and 13th March. Our stand number is 90, pop along and say Hello

All posts by generateuk

Tech Turkey Day – 27th March

Tech Turkey Day- see the flyer below for details.

CWST exhibiting at the Surface World Show in Birmingham

CWST will be exhibiting at the Surface World Show in Birmingham on the 26th and 27th February 2025. Our stand number is B12, pop along and visit us

CWST at the MedTec Live Innovation Expo

CWST will be exhibiting at the MedTec Live Innovation Expo in Nurnberg Germany on the 18th – 19th February 2025. Our stand number is 10, please come along and say hello

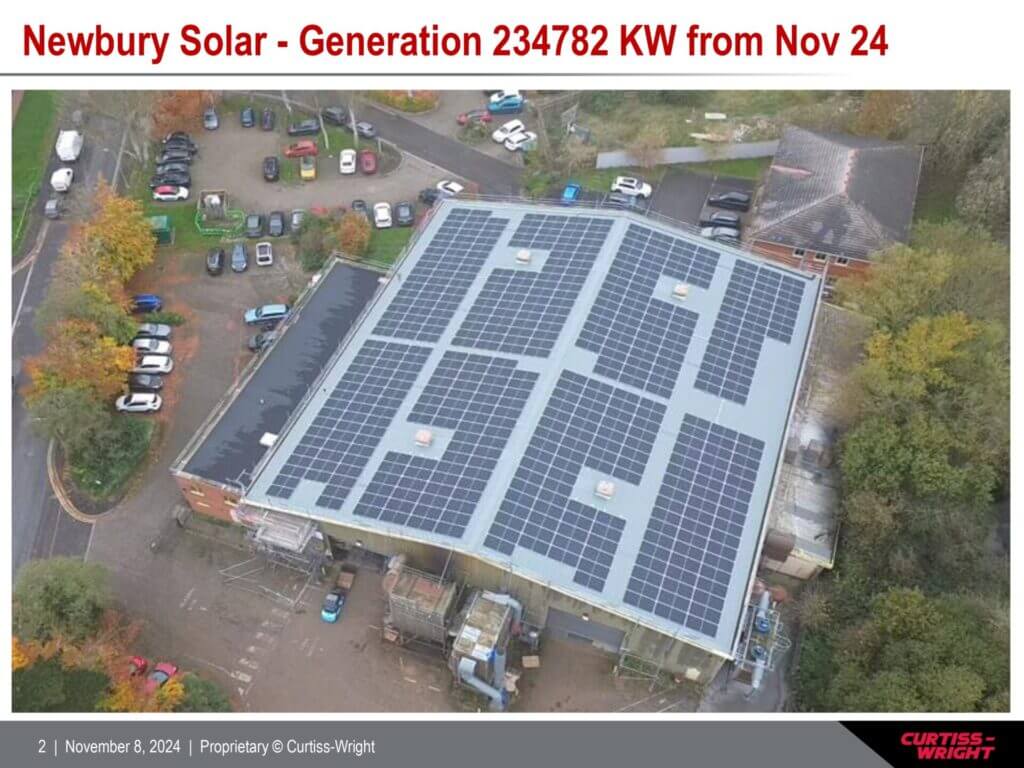

Newbury Facility Going Green with New Solar Panel Installation

Everlube® Products Achieves PFAS Compliance with Transition To PTFE Grades and Launches Fluropolymer-Free Dry Film Lubricant

Curtiss-Wright Launches Parylene Conformal Coating Capabilities in the United Kingdom

CWST will be Exhibiting at MedTec Ireland in September

CWST will be exhibiting at the MedTec Ireland show on the 25th – 26th September, our stand number is 77, come along and say Hello

CWST exhibiting at Engineering Solutions Live 2024

CWST will be exhibiting at the Engineering Solutions Live event at the British Motor Museum, Gaydon on 21st March 2024, our stand number is 21.

Pop along and say “Hello”

Hungarian Facility Ribbon Cutting Ceremony

Please see the press release here regarding the Hungarian Facility Ribbon Cutting Ceremony

Curtiss-Wright’s Keronite Business Secures Nadcap Approval Certification

Curtiss-Wright Surface Technologies Division today announced that its Keronite business, a world leader in plasma electrolytic oxidation (PEO) applications including a pioneering surface treatment that uniquely enhances the performance of light alloys, has successfully secured Nadcap accreditation for Chemical Processing at its Greenwood, IN facility.

Curtiss Wright India Awarded 2nd Place For Technical Solution in Thermal Generation

An Indian energy trade organisation has awarded Curtiss-Wright Surface Technology India division 2nd place for “Best Technical Solution in the Thermal Power Generation Process”.

The overall goal set by the company, was to increase the service life of the super charger boiler tubes and improve the microstructure of the tube, by inducing compressive stress. CWST India achieved this through our virgin boiler tube ID peening processes.

To find out more about this and how our India facility achieved this prize view our press release.

Curtiss Wright Surface Technology Opens New Facility in Hyderabad, India

Curtiss Wright Surface Technology has announced the opening of its Hyderabad facility in India. This is the 2nd facility in the country and will be providing a variety of services including shot peening, dry blasting and boiler tube ID peening.

This new facility will support the growing power generation industry in India as well as become a hub for aero structure and MRO operations.

Find out more about the new facility in CWST’s latest press release.

CWST Exhibiting at Engineering Solutions Live 2023

Once again, we will be exhibiting at Engineering Solutions Live at the British Motor Museum, Gaydon on 23rd March 2023.

We will be at Stand 21 so make sure you come and say hello.

About Engineering Solutions Live

Engineering Solutions Live is packed full of seminars and exhibitor stands covering a wide array of engineering topics. From Fastening and Joining to PCB, you can improve your knowledge in certain areas, make new contacts within the industry and collaborate with some of the biggest names in engineering in the UK.

To find out more about the event visit the Engineering Solutions Live site or register for your space.

Curtiss-Wright Acquires Kernoite Group LTD

A Leading Global Supplier of Plasma Electrolytic Oxidation Surface Treatment Coatings

DAVIDSON, N.C.–(BUSINESS WIRE)– Curtiss-Wright Corporation (NYSE: CW) today announced that it has completed the acquisition of the stock of Keronite Group Limited (Keronite) for $35 million in cash. Keronite is a leading provider of Plasma Electrolytic Oxidation (PEO) surface treatment applications offering corrosion protection, wear resistance, thermal protection and electrical insulation for the defense, commercial aerospace and industrial vehicle markets, and also in semiconductor manufacturing.

Keronite is expected to generate sales of approximately $9 million in 2022 and is expected to be neutral to Curtiss-Wright’s adjusted diluted earnings per share in its first full year of ownership, excluding first year purchase accounting costs, and produce a strong free cash flow conversion rate of approximately 100%. The acquired business will operate within Curtiss-Wright’s Aerospace & Industrial segment.

“The acquisition of Keronite increases the breadth of our surface treatment services portfolio with unique and complementary coatings technologies recognized for their critical performance in severe service environments,” said Lynn M. Bamford, Chair and CEO of Curtiss-Wright Corporation. “The combination of this business with Curtiss-Wright’s long-standing customer relationships and global sales channels provides strong alignment to the strategic priorities as highlighted at our 2021 investor day and is expected to yield significant opportunities for long-term profitable growth.”

Keronite’s PEO surface treatment process utilizes a bath-based method of producing ceramic layers on light alloys such as aluminum, magnesium and titanium to enhance their inherent performance characteristics. As the surface is oxidized, it incorporates an electrolyte thereby giving the coating specialized characteristics that are tailored to the specific application. Through Keronite’s process, lightweight metals are afforded the wear and performance properties of high-weight materials such as carbide or steel in a more environmentally-friendly manner, and are well-suited to support demanding applications such as aerospace or electric vehicle programs.

Keronite, which was founded in 2000 and employs nearly 45 people, is based in Cambridge, UK, and also maintains operations in Greenwood, Indiana.

About Curtiss-Wright Corporation

Curtiss-Wright Corporation (NYSE:CW) is a global integrated business that provides highly engineered products, solutions and services mainly to Aerospace & Defense markets, as well as critical technologies in demanding Commercial Power, Process and Industrial markets. We leverage a workforce of 8,000 highly skilled employees who develop, design and build what we believe are the best engineered solutions to the markets we serve. Building on the heritage of Glenn Curtiss and the Wright brothers, Curtiss-Wright has a long tradition of providing innovative solutions through trusted customer relationships.

This press release contains forward-looking statements made pursuant to the Safe Harbor provisions of the Private Securities Litigation Reform Act of 1995 that are based on management’s beliefs and assumptions. Such statements, including statements relating to Curtiss-Wright Corporation’s expectations for the future opportunities associated with the acquisition, the success of transferring Keronite’s technology throughout our existing world-wide network, and the success of the Company integrating Keronite into its Aerospace & Industrial segment are not considered historical facts and are considered forward-looking statements under the federal securities laws. Such forward-looking statements are subject to certain risks and uncertainties that could cause actual results to differ materially from those expressed or implied. Readers are cautioned not to place undue reliance on these forward-looking statements, which speak only as of the date hereof. Such risks and uncertainties include, but are not limited to: a reduction in anticipated orders; an economic downturn; changes in competitive marketplace and/or customer requirements; a change in US government spending; an inability to perform customer contracts at anticipated cost levels; and other factors that generally affect the business of aerospace, defense contracting, marine, electronics and industrial companies. Please refer to the Company’s current SEC filings under the Securities Exchange Act of 1934, as amended, for further information.

Jim Ryan

(704) 869-4621

jim.ryan@curtisswright.com

Source: Curtiss-Wright Corporation

Upcoming site closure

Following the very sad news regarding the passing of HM The Queen, all our CWST UK sites will be closed on Monday 19th September 2022 to allow our staff to pay their respect to the Queen.

CWST Exhibiting at the MedTec Ireland Event

CWST will be exhibiting at the MedTec Ireland event on the 21st – 22nd September. Our stand number is 77. Please come along and say hello

Chester Division celebrates another successful (AS)EN9100 Audit

Our Chester Division has successfully undergone it’s annual (AS)EN9100 audit and for the second year running this was completed with ZERO findings.

“The auditor was full of praise for our systems/databases and most importantly our employees who again represented the company with distinction, showing the great dedicated people we have working here at MIC Chester!” – Gary Sharples (Quality Manger)

Introducing Fluregiene 200™

Curtiss-Wright Surface Technologies, Everlube® Coating Products have partnered with BioCote® to expand their fluoropolymer coating product range to create Fluregiene 200™: an antimicrobial coating that is ideally suited for many surfaces and environments.

Based on existing Everlube® coating technology, the new Fluregiene 200™ is a unique fluoropolymer coating that offers low friction, easy-clean properties combined with superb chemical and abrasion resistance. With a view to improving hygiene standards, Everlube® Coatings have integrated BioCote® antimicrobial technology to protect the coating from microbes such as bacteria, mould and fungi. Benefits of applying antimicrobial technology into the Fluregiene 200™ include:

Anti-fouling

- Low COF Surface coating (0.08 – 0.2 static)

- Corrosion resistance and excellent chemical resistance

- Excellent chip and abrasion resistance

- Reduces and prevents build-up of contaminates

- Excellent flexibility

- Dirt and debris less likely to attach to the surface

Microbial & bacteria growth inhibitor

- Using patented BioCote® antimicrobial technology against microbial growth

- Inhibits and reduces microbial growth on protected coating

- Protects treated surfaces against bad odours, staining and material degradation

Easy clean and reduced cleaning intervals

- Provides continual microbial reduction on coating

- High PTFE content allows easy wipe down and cleaning

- Provides more hygienic and cleanable surface than brushed or finished steels

Applicable to a wide range of parts and components such as door handles, elevator buttons, airport seating and gym equipment, the Fluregiene 200™ will be highly beneficial for these surfaces. BioCote® also has real-life data to support the application of this antimicrobial technology in environments such as health care, transport, education, public areas and much more.

For more information on Fluregiene 200™ and Everlube® Coating Products please contact our coatings team on:

- Tel: (44) 1386 421444

- Email: emukenquiries@cwst.com

Engineering Solutions Live

We’re delighted to be exhibiting at Engineering Solutions Live 2022, which is now open for registrations!

Returning to the British Motor Museum in Gaydon on Thursday 24th March 2022, Engineering Solutions Live is your one-stop-shop for new contacts and thought leadership in the engineering sector.

Configured for busy design and production engineers, the event provides the opportunity to visit market-leading suppliers and solution providers, network with senior decision-makers from across the UK and boost your learning during our expert-led conference sessions.

Visit www.engineeringsolutionslive.co.uk to find out more and to register for your FREE ticket!

CWST at Engineering Solutions Live 2022

CWST are exhibiting at the Engineering Solutions Live at the British Motor Museum, Gaydon on 24th March.

Come along and say hello!

CWST at Engineering Solutions Live

CWST will be exhibiting at the Engineering Solutions Live show at the Coventry Building Society Arena (previously Ricoh Arena) on the 19th and 20th October, come along and say Hello to us at stand number 21

Curtiss-Wright Surface Technologies Virtual Exhibition Stand

We’ve really missed you!

Curtiss-Wright Surface Technologies have been unable to welcome visitors to our exhibition stands and events for over a year now and we hope this will change in the not too distant future!

In the meantime we would love the opportunity to showcase our world leading processes and surface treatments for you through our new fully interactive virtual exhibition stand from the comfort of your office, garden or sofa!

You will find examples of some of the critical parts and materials we process along with video presentations, animations and information on how we can help be your single source for critical surface treatments.

You can find contact information for all of our surface treatment experts and facility locations from the components on display and we look forward to assisting you with your applications and design challenges.

Now take a look!

New CW Company video

50th Anniversary of our Derby facilities

As is the case in many fast moving industries, we spend our time improving our operations and developing our technologies, focussing on our goal to achieve excellence in our performance in support of customers. It then comes, as a pleasant surprise, to reflect upon our operational history and realise that this June is the 50th anniversary of the CWST Derby Business Unit.

In 1970 Metal Improvement Company (CWST) reached an agreement to provide a shot peening service to a local Aerospace OEM with their first venture in the UK. The original suite of machines were installed and work commenced in early 1971 as a shop in shop operation. With local industries learning of the great advantages of shot peening in overcoming fatigue failures it was not long until in the demand on our services required us to build a purpose designed plant on Ascot Drive in Derby 1984.

Since that time we have continually strived to push the technology of shot peening forward, working with our customers to define new and testing specifications based around 4 generations of computer controlled robotic machines each adding more finite control supplemented by unique and bespoke delivery tools and methods.

In addition to our shot peening abilities we bring the same technological approaches to customers Thermal spray challenges, introducing both HVOF and Plasma spray capabilities into the facility.

It has been the dedication and professionalism of our employees that has driven us along this path for the last 50 years, so it’s a very Happy 50th Birthday to CWST in Derby and an even bigger thankyou to all customers and employees, past and present, who have helped us on our journey.