Taking it back to basics, at CWST we are experts in metal surface finishing treatment processes. But what does this really mean, and what are the different metal surface treatments we provide?

Simply, that we have vast knowledge in a range of industrial processes that alter the surface of metal to achieve a certain property, for example, to improve appearance, adhesion, corrosion resistance, hardness and much more. Our metal surface treatments can be categorised by how they affect the subject, either removing/reshaping the finishing, or adding/altering the finishing.

What metal surface treatments do we provide?

At CWST we offer a wide variety of key metal surface treatments, finishes and processes. Each surface finishing process increases performance and life of metal components by protecting against premature failure, due to fatigue, corrosion, stress, fretting, friction and galling, as well as support against environmental and thermal variation.

Our high-performance metal surface finishing treatments include the following.

Controlled Shot Peening

Tensile stresses induced during welding, grinding, machining and heat treatment are replaced with beneficial compressive stresses proven to prevent fatigue and stress corrosion cracking.

This cold working process is applied using spherical media known as ‘shot’, as each piece hits the surface it creates an indentation where the surface will attempt to yield but is restrained by the substrate material. This in turn causes the material to compress, creating added stress – making the surface crack resistant and removes any prior manufacturing tensile stress.

Find out more about Controlled Shot Peening.

Shot Peen Forming

This surface treatment creates curvature in aircraft wing skins to enhance lift and efficiency and to protect against fatigue. Shot peen forming is also used to correct the distortion of components following manufacturing.

Within this process, control spherical media is fired at the surface, creating indentations causing the material to elastically stretch, however it is restrained by the substrate. This causes the surface to arc towards the peened side, resulting in curvature. This metal surface treatment method can induce stress to greater depths, with a tighter radius of curvature as well as being able to be performed on thicker materials.

Find out more about Shot Peen Forming.

Laser Peening

Laser peening induces compressive stress with precision accuracy into key areas of a component up to 5 to 10 times deeper than other conventional cold working techniques.

This metal surface treatment uses an output beam at 25 joules at 18 nanoseconds from a glass laser, a thin stream of water is made to flow across the surface and the laser transparently passes through the water, and a pulse is absorbed on the metal surface. The rise in pressure creates a shock wave that penetrates into the metal, straining the surface layer.

Find out more about Laser Peening.

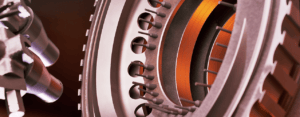

C.A.S.E. Isotropic Finishing Super Finishing

Removes surface asperities to create a mirror like finish, reducing macro and micro-pitting, oil temperature and noise whilst promoting lubricant retention.

This surface treatment uses controlled shot peening, followed by chemical surface superfinishing. This removes any metal asperities, creating a surface with a negative skew (Rsk) retaining valleys for optimum oil retention, reducing surface friction and operating temperatures.

Find out more about C.A.S.E Isotropic Superfinishing.

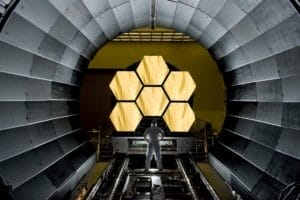

Thermal Spray Coatings

Wear resistant and barrier thermal spray coatings such as HVOF, arc and flame spray, protecting against high temperatures, wear, corrosion and oxidation, as well as restoring parts to their original dimensions.

This coating process uses a heated powder or feedstock which is propelled at high velocity, using kinetic energy formed from a gas stream, onto the surface. This forms a mechanical bond with the substrate as it cools – building up thickness and density.

Find out more about Thermal Spray Coatings.

Engineered Coatings

Alongside our metal surface treatment, using the correct coating system and dry film lubricants will also extend the life of critical components by reducing, friction, wear galling, fretting, corrosion, and environmental damage providing a reduction in maintenance and service costs.

Plasma Electrolytic Oxidation (PEO) Keronite

This unique process produces a ceramic layer on surface of light alloys such as Titanium, Magnesium and aluminium. The resulting surface is extremely hard, corrosion and wear resistant and provides extensive weight saving performance benefits to light alloy components.

Find out more about Keronite PEO Keronite | Advanced Surface Treatments for Light Alloys

Our range of industrial protective coatings includes:

- Thermal Spray – Providing thermal management, corrosion and erosion, component protection and repair of turbine components.

- Solid Film Lubricants & Liquid Component Coatings – Long lasting lubrication in harsh operating conditions and to prevent friction and galling.

- Parylene Conformal Coatings – Biocompatible, ultra-thin coating used to reduce friction and protect components from the environment, commonly used for medical devices and electronic applications.

Find out more about Engineered Performance Coating Services.

Parylene Conformal Coatings

Parylene is a highly lubricious and ultra-thin conformal coating with outstanding chemical, moisture and electrical barrier protection for metals, elastomers, electronics and plastic.

This surface treatment process is applied by vapour deposition under a vacuum, in a coating chamber at ambient temperature. It involves exposing objects to a gas-phase monomer at low pressure, and through vacuum deposition the Parylene condenses and polymerises on the component’s surface – increasing the thickness.

Find out more about Parylene Conformal Coatings.

Wet Treatments (Anodising)

Surface treatments such as wet processing techniques improve atmospheric and chemical corrosive resistance and also enhance the application of paint primer and adhesives.

Find out more about Wet Treatments.

Material Analysis and Testing

IMR Test Labs offer mechanical and metallurgical testing including material testing, failure analysis, chemical analysis and weld testing to ensure design and manufacturing integrity.

IMR’s comprehensive range of mechanical, chemical and metallurgical testing services ensure design and manufacturing integrity for our customers. These material testing services range from the verification of raw materials through to in depth failure analysis.

Find out more about our IMR Testing Services.

Onsite Services

Specialist teams can be mobilised worldwide to repair large or fixed equipment, reducing shipping costs and downtime to the same specification as in-house processing.

Our onsite services include spraying, surface treatments, component repair and a range of overhaul services. Due to the processing of plant equipment which cannot be moved due to size and fixed installations.

Find out more about our Onsite Services.

Peentex Architectural Finishes

PEENTEX protects internal and external cladding, street furniture and signage. Creates a decorative finish for architectural purposes on metal, glass, wood and acrylic. Non-slip textured finish for tooling and equipment.

We are able to accurately control and repeat the peening process to produce a range of different textures and engineered surface treatments and finishes creating highly decorative designs and finishes. It is often practical for users for high traffic areas as the finish diffuses direct light and glare, disguising fingerprints and mild blemishes.

Find out more about Peentex Architectural Finishes.

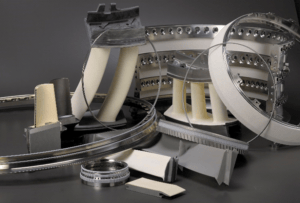

Peenflex Protective Mouldings

PEENFLEX damage and abrasion resistant mouldings protect parts through the various stages of processing, lifting, moving, storage and despatch. Uniquely made for each application.

All our protective mouldings and maskings are rigorously tested to ensure a high quality of wear resistance enabling them to be recycled many times through the handling stages and presenting a cost effective solution to damage prevention.

Find out more about our Protective Moulding and Masking.

Contact the team at CWST to explore our range of Metal Surface Finishing Treatment Processes, we will help you discover which of our specialist treatment is right for your components.